Snap-Z Case Study: Can it Fix a Wavy Ridge Cap?

Today we are taking a look at the real-world performance of the Snap-Z ridge vent.

Winter is fast approaching. And so is the potential for extreme oil-canning on a metal roof ridge cap.

The waves in a ridge cap – usually refereed to as oil-canning – is caused by the expanding and contracting of the steel with ambient temperature swings. Because the ridge cap is fastened with pop rivets at every 16″ to 19″ intervals (depending on the size of the panel) the steel has nowhere to go but up.

Most of the time oil-canning is very minimal and barely noticeable. But if a ridge cap was installed on a very cold day – when the steel was at it’s most contracted state – chances are it will suffer from extreme oil-canning once warmer temperatures climb and the steel begins to expand.

That is exactly the case with the house below where the ridge cap was installed on a cold, winter day in 2016. The oil-canning was painfully visible once warmer weather arrived.

And there was not really much that could be done.

Or was there?

Fast-forward a few years to when the Snap-Z comes on the scene.

The Snap-Z ridge vent is new to the marketplace, but it makes a lot of promises. It’s one of those ideas that are so insightful and yet so simple, that you’re left wondering, “Why didn’t I think of that?”

What is a Z-Closure?

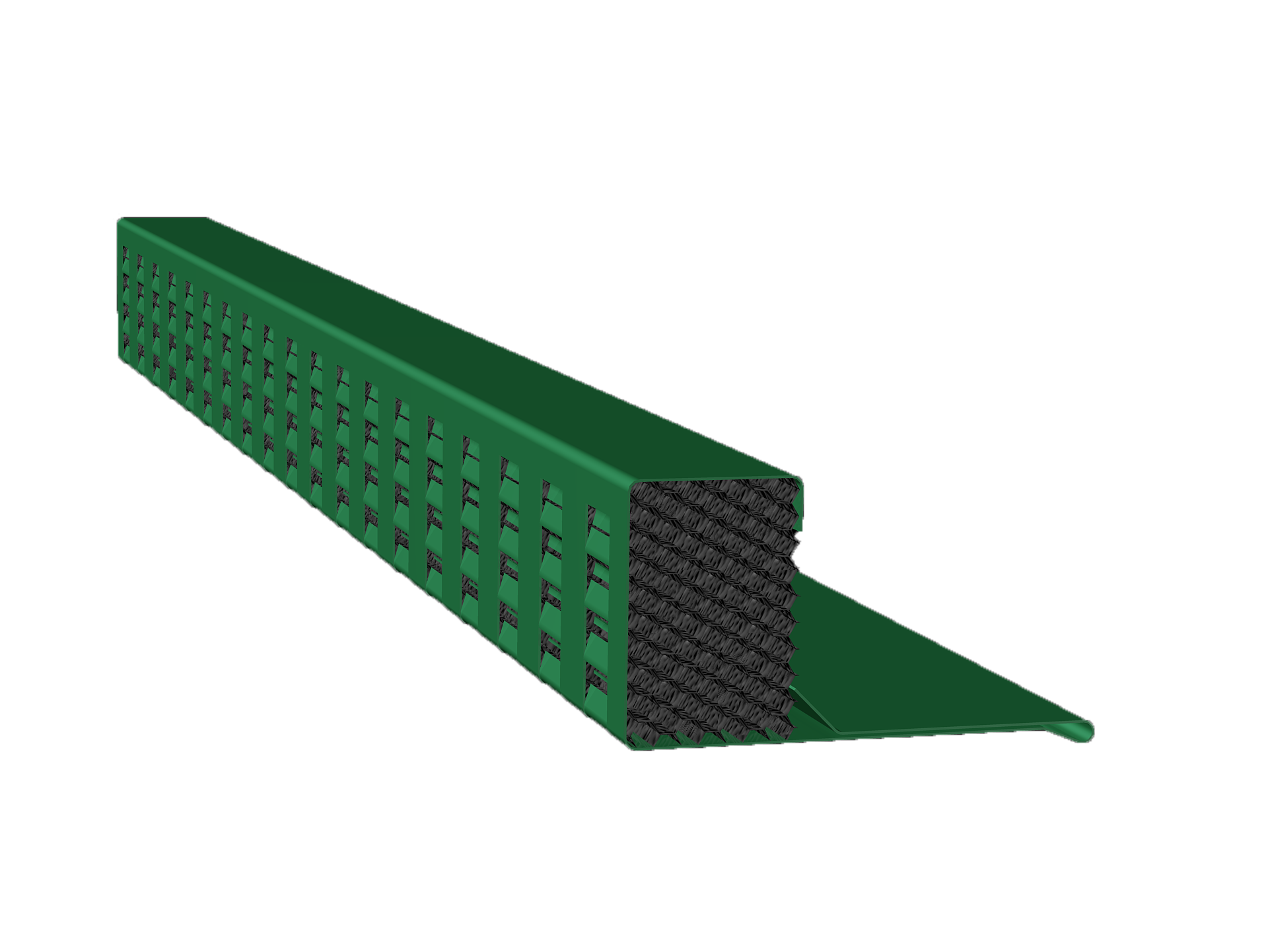

First off, the Snap-Z is similar to a standard z-closure, but with added bonuses. The purpose of a z-closure is to fill the void between the ribs of a standing seam panel and provide support for the ridge cap to fasten to. The z-closures are often perforated to allow airflow as a vent for the attic. Behind the perforations is a channel that holds a woven, mesh insert to prevent snow, dirt, and bugs from getting through.

The Snap-Z is different from a regular z-closure in 3 ways.

Pre-installed Butyl Tape

First, the Snap-Z has pre-applied butyl tape to the bottom. Not only is this one less (usually) messy step that you would otherwise need to do, but it also prevents it from sliding down the roof while waiting to get fastened. It’s as simple as peeling off the paper backer and pressing it down along your chalk line… you did remember to snap a line, right? You can even increase efficiency by doing a pass sticking the Snap-Z’s and then a second pass fastening them… instead of sticking one, then stopping to grab your impact and screws, then stick another one… you get the idea.

Pre-Punched Snap-Z

That brings us to the second advantage. The Snap-Z has pre-punched screw slots! Need I say more? No more spunout screws scratching the panel. No more pre-drilling 3-layers of steel… and cleaning the butyl caulk out of the drill bit later. This is a major time saver.

Installs with a Snap

Regular Z-closure

Snap-Z Closure

Third, the Snap-Z is different from a regular z-closure due to it’s extra wide flange on top that is engineered for an open hem ridge cap to snap into place…hence the name. The advantage of the snapping design is that something other than just pop-rivets is holding the ridge cap in place. In fact, it only requires 50% of the usual fasteners.

Yes, that saves time on the job. But what really interest us is whether the 6-less pop-rivets per 10′ of ridge cap can minimize oil-canning.

There is only one way to find out.

The Snap-Z Case Study

So we got permission from the homeowner to replace the ridge vents with Snap-Z’s. And we partnered with Snap-Z (standingseamroofvent.com) to create a case study where the honest results would be published either way.

This wasn’t meant to be a scientific test, but we figured the difference, if there would be any any, would be easy to see.

You can see the details of how the contractor removed the old ridge cap and vents in the video below.

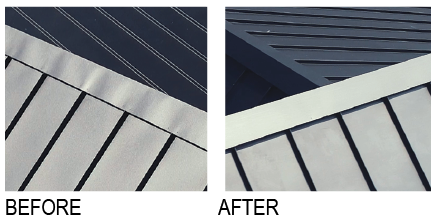

After removing the ridge cap and applying the Snap-Z’s, our photographer went back after a few months of exposure to get some “after” shots.

The difference is pretty stark.

So what is the take away?

- Avoid installing ridge caps on super-cold days.

- If that is not possible, using the Snap-Z can greatly minimize oil-canning.

- Use Snap-Z if you want to save installation time. They say, “Time is …”

Since you brought it up, I know what you’re thinking. “Yeah, but the Snap-Z probably costs twice as much as a regular z-closure.” Ha! Actually, they cost the same. I repeat, there is currently NO price difference between the Snap-Z and a regular z-closure.

So what’s the catch? Well, we only stock the Snap-Z in black.

But hold on. Take a look at the picture below. Can you tell me what color the z-closure is?

No, you can’t. We can’t either. So it’s not a catch after all.

So that about wraps it up. You’ll find the Snap-Z stocked in black at your closest A.B. Martin Roofing Supply.

But before you go, you might enjoy this fun video we made for our customer appreciation event.